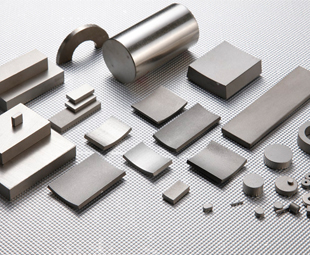

Sintered NdFeB

Ndfeb permanent magnet material appeared in the early 1980 s, magnetic can be very high. It (BH) Max value of 5-12 times the ferrite magnets, alnico magnets is 3-10 times; Its coercive force equivalent to five to ten times the size of ferrite magnets, alnico magnets 5-15 times, its high magnetic potential, can suck up the equivalent of a weight of 640 times its own weight.

The deficiency of ndfeb magnet is its temperature performance is poor, at high temperatures using magnetic loss is bigger, the highest working temperature is low. General is 80 degrees Celsius, after special processing of the magnet, the highest working temperature can reach 230 degrees Celsius.

Because of the permanent magnetic material contains a large number of neodymium and iron, so the ndfeb magnet is basic for surface coating processing. Plating nickel (Ni), zinc (zinc), gold (Au), chromium (Cr), Epoxy resin (Epoxy), etc.

Because of ndfeb magnet mechanical properties than samarium cobalt magnet and alnico magnets, easier to cutting and drilling and complex shape processing. Ndfeb magnet is widely used in mechanical and electrical, communications, electronics, computer, aerospace, wind power, automobile, medical treatment and magnetic separation, magnetic levitation, oil industry and other fields. And non-technical areas is also very widely used.